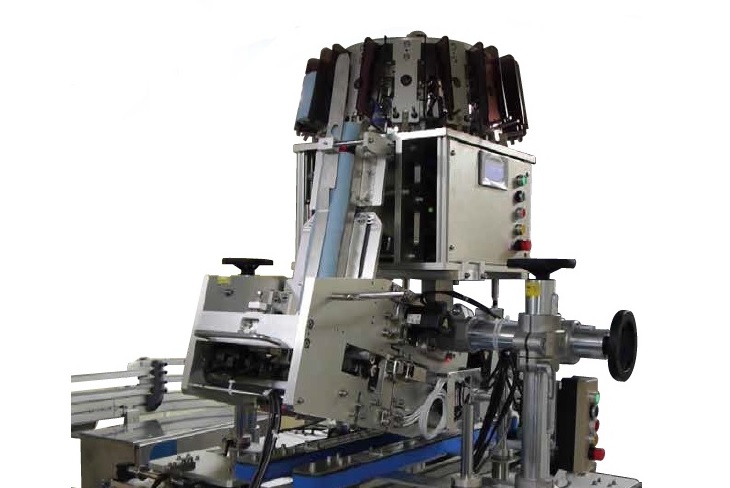

Neck POP Labeler : TLN-1000

A labeler that attaches the neck POP to the bottle neck.

Features

Significant efficiency improvements are achieved by automating manual works

When attaching a large number of neck POP labels manually, it is often necessary to unpack the cardboard boxes containing the products in a different location from the production line and perform the task. This method requires a certain number of workers and workspace.

By using the labeler, neck POP labels can be automatically attached within the production line (inline), and all tasks are completed within the line, just like the normal process. Eliminating the post-packaging tasks results in a significant improvement in work efficiency and cost reduction.

Processing capacity that can accommodate high-speed production lines

This labeler is capable of handling high-speed production lines that are mass-produced daily, such as soft drinks.

[Image of Processing Capacity]

When calculating based on an 8-hour working day, attaching 1 million neck POP labels to PET bottles:

If done manually, it would require 20 workers for 20 days. In contrast, with the Neck POP Labeler, the task can be completed in as short as 2 days.

It requires fewer label supply cycles

Various functions to support stable labeling

Equipped with a side-hold belt, it ensures stable flow of products on the conveyor.

In addition, products with neck POP labels that fail to attach properly are automatically detected by the "non-attachment sensor" and removed from the line by the NG discharge device, preventing the flow of defective products.

Compatible with various bottle shapes

It is compatible with products such as 500ml, 1.5L, and 2L PET bottles, glass bottles, and bottle cans.

Specifications

Capacity: |

1,000 labels/minute |

|---|---|

Line Speed: |

90m/minute |

Feeder stock capacity |

10,000 labels (single-layer type) |

Size of Neck POP Labels that can be Set: |

Width: 60-100mm Length: 55-80mm |

Drive System: |

Servo Motor |

Power Supply: |

AC200V single-phase |

Electric Power Capacity: |

3.0KVA |

Weight: |

360Kg |

Air: |

0.5MPa |

Other |

Side Hold Belt |

Capacity: |

800 labels/minute |

|---|---|

Line Speed: |

58m/minute |

Feeder stock capacity |

7,200 labels (single-layer type) |

Size of Neck POP Labels that can be Set: |

Width: 80mm Length: 55-65mm |

Drive System: |

Servo Motor |

Power Supply: |

AC200V single-phase |

Electric capacity |

1.5KVA |

Weight: |

80Kg |

Air: |

0.45MPa |

Other |